protec carrier systems

machinery

Machinery

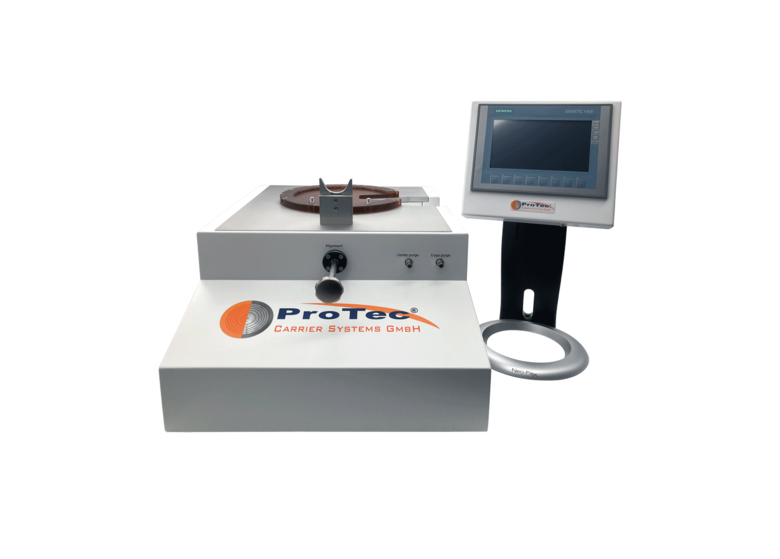

MCU 3000

The manual chucking unit (MCU 3000) is used to temporarily bond and debond the device wafer with transfer electrostatic carriers, the T-ESC®s. It is suited to low volume or R&D production. A trained operator can achieve between 15-25 bonds and debonds per hour. It comes with a touch screen for operation and a handling unit to do the bonding and debonding. A manual alignment feature is included and can be used by the operator.

The MCU 3000 is available in three standard sizes but customized versions are also available. The change from one wafer size to another is done very quickly and reliably in 10 minutes. In addition, we always provide special training and support for your operators.

MCU 3000

Typical Applications

-

Flexible use of substrate sizes by changing the working unit

-

Enhanced dechucking feature

-

Programmable chucking voltage and high sensitive current measurement

-

Enhanced controller: contains the GUI and several (self) diagnostic features

-

LCD touchscreen panel includes selectable screen display for voltage, current and status information, customer’s chucking type settings and process conditions, etc.

-

Parameter configuration settings: are stored in customized data and recorded for each carrier type

Technical Data

Three Basic Sizes:

3"/4”/6”, 6”/8”, 8”/12” and

customized versions on request

Weight:

20 kg

Process Media:

Power supply

N2 (CDA/compressed air),

Vacuum

Machine Dimensions:

L x W x H:

621 x 430 x 330 mm

Selectable Chucking Voltage:

0 to 3kV