protec carrier systems

Products

Semiconductors, Machines, Carriers and your Special Solution

coating on standard equipment, temporary bonding without adhesives, gripping and fixation of sensitive substrates. Highest yield even for fragile substrates can be generated for inline- as well as cluster-based processing tools.

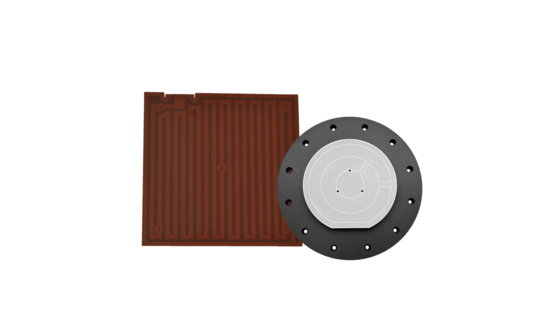

Electrostatic Chuck (ESC)

The ESC technology by ProTec® offers the solution for demanding processing on new or even existing equipment.

Learn More

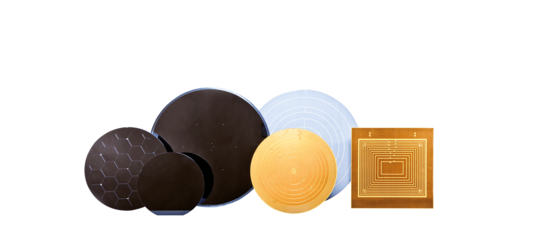

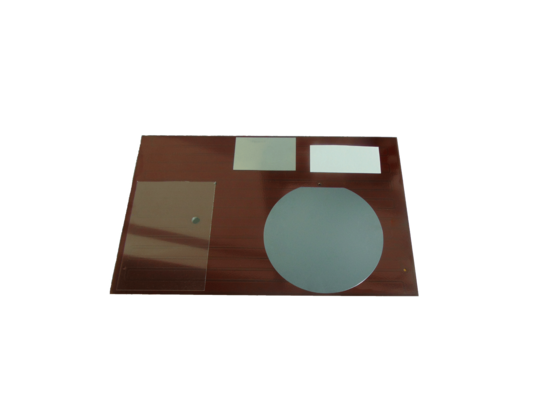

Transferable Electrostatic Carrier (T-ESC®)

The T-ESC® technology by ProTec® offers safe and easy handling as well as processing of fragile, thin and ultra-thin substrates.

Learn More

Special Solutions

Find special solutions for your product based on our touchless gripping by electrostatic energy fields.

Learn More

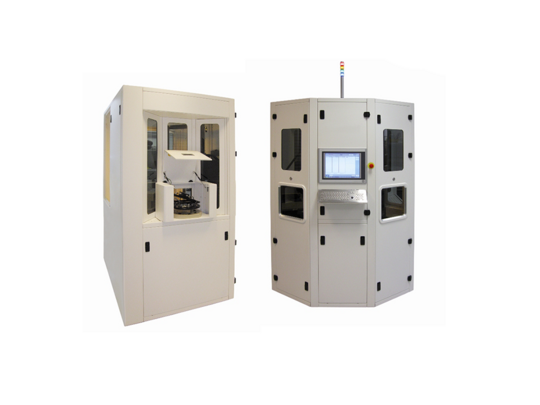

ACU 3000

ProTec®'s automated chucking unit (ACU 3000) is built for high volume temporary bonding and debonding applications with up to 120 wafer + T-ESC® packages per hour.

Learn More

MCU 3000

The manual chucking unit (MCU 3000) is used to temporarily bond and debond the device wafer with our T-ESC®s. It is suited for low volume or in R&D production areas.

Learn More

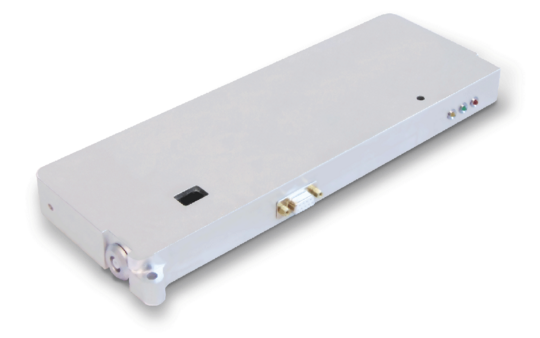

Electrostatic Chuck Power Supplies

ProTec®'s electrostatic chuck power supplies make it possible to accurately control the fixation of substrates on e-chucks during the manufacturing process.

Learn More

Racket Bipolar

The ProTec®(TOR) racket bipolar is an easy-to-use tool for transferring fragile substrates such as ultra-thin wafers, glass or conductive and non-conductive foils.

Learn More

FAQ

If you have any questions about our technology, you can find the most popular answers here. Otherwise please feel free to contact us.

Learn More

News

In our news-list you can find the highlights of our company. E.g. "ProTec offers the solution for mass production of MicroLED's"!

Learn More