Electrostatic Chuck (ESC)

The ESC technology by ProTec® offers the solution for demanding processing on new or even existing equipment, leading to a better cost of ownership and an easy integration of new processes on already existing lines, such as thin glass coating on standard equipment. Highest yield also for fragile substrates can be generated for inline- and also cluster-based processing tools.

Our electrostatic fixation systems are specifically designed to the needs of our customers, e.g. chucking multiple glasses (also 3D type) on a mobile electrostatic carrier and guiding them through an inline plasma coating step or for temperature-controlled wafer processing during demanding plasma steps.

Optical Bonding

Handling

Substrate Bending

Our Machines

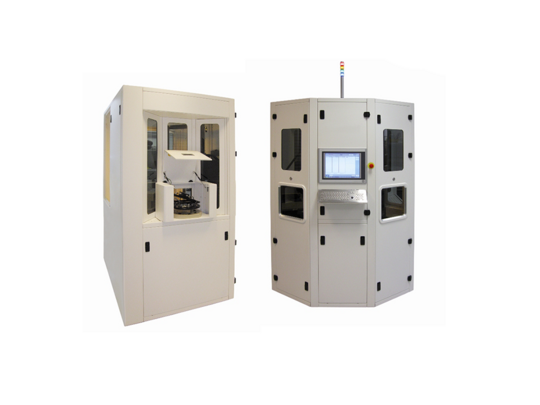

ACU 3000

A fully automated electrostatic chucking/de-chucking unit with up to 120 wafers and/or T-ESC® packages per hour, guaranteeing the highest yield during handling and many diagnostic features.

Learn More

MCU 3000

A manual chucking / de-chucking unit of thin and ultra-thin substrates on carriers (T-ESC®s) for flexible sizes from 4”/6” to 8”/12” with a high flexible mobile handling tool and diagnostic features.

Learn More