protec

what is new

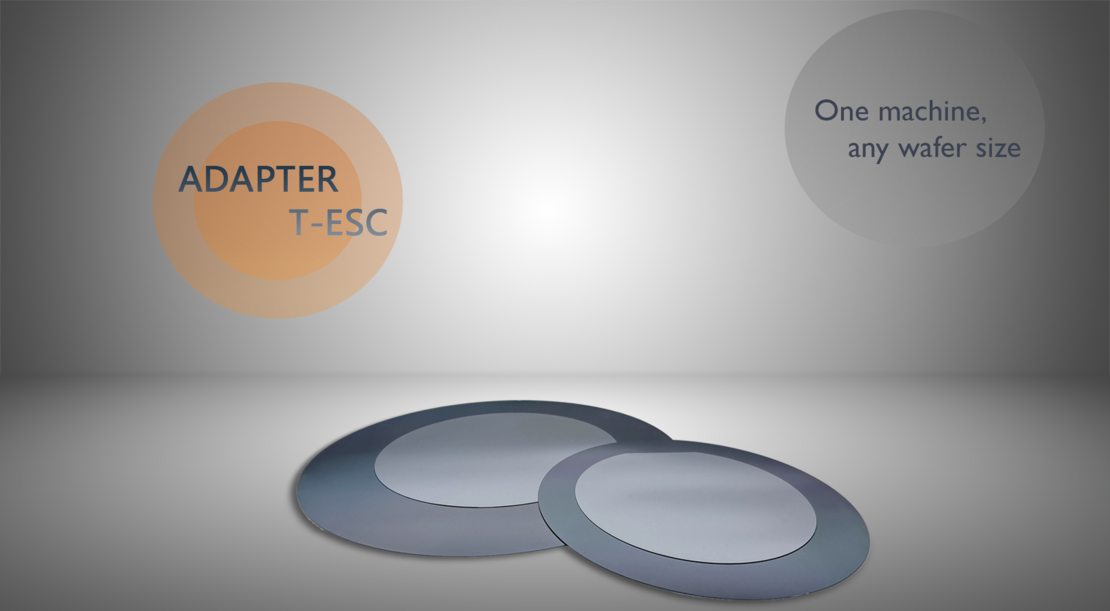

Adapter T-ESC - Stimulate your turnover by increasing your production scope

A significant number of semiconductor production facilities are equipped with machines that are compatible with only one wafer size. However, over time new projects come up and former fitting sizes and shapes are not suitable anymore. Until now, there was no solution to address this problem without significant investments such as replacing existing equipment or losing the project.

ProTec®’s Adapter Transfer Electrostatic Carrier (T-ESC) provides the solution for the needed size changes. Instead of purchasing new machinery or machinery parts to process wafers of different sizes, simply use the Adapter Carrier which allows you to run different wafer sizes and shapes on your existing equipment.

A good example of this is the Stepper process.The Stepper machine is typically designed for only one wafer size and it is one of the highest priced machines within the fab. With a 4”/8” Adapter Carrier the Stepper machine can for example now process a 4” device wafer on an 8” Stepper. The 4” wafer is temporarily bonded to an 8” Adapter T-ESC within seconds using electrostatic forces. The 8” Stepper tool now recognizes a standard 8” wafer and can process smaller 4” wafers. During the entire Stepper process the wafer is firmly attached to the temporary carrier.

What makes the Adapter T-ESC special is that the temporary bonding is adhesive-free and it is reusable several hundred times, keeping the running costs as low as possible.

In contrast to pocket wafers the Adapter Carrier holds the device wafer in position allowing applications were no movement and alignment accuracy is needed.