Transferable Electrostatic Carriers

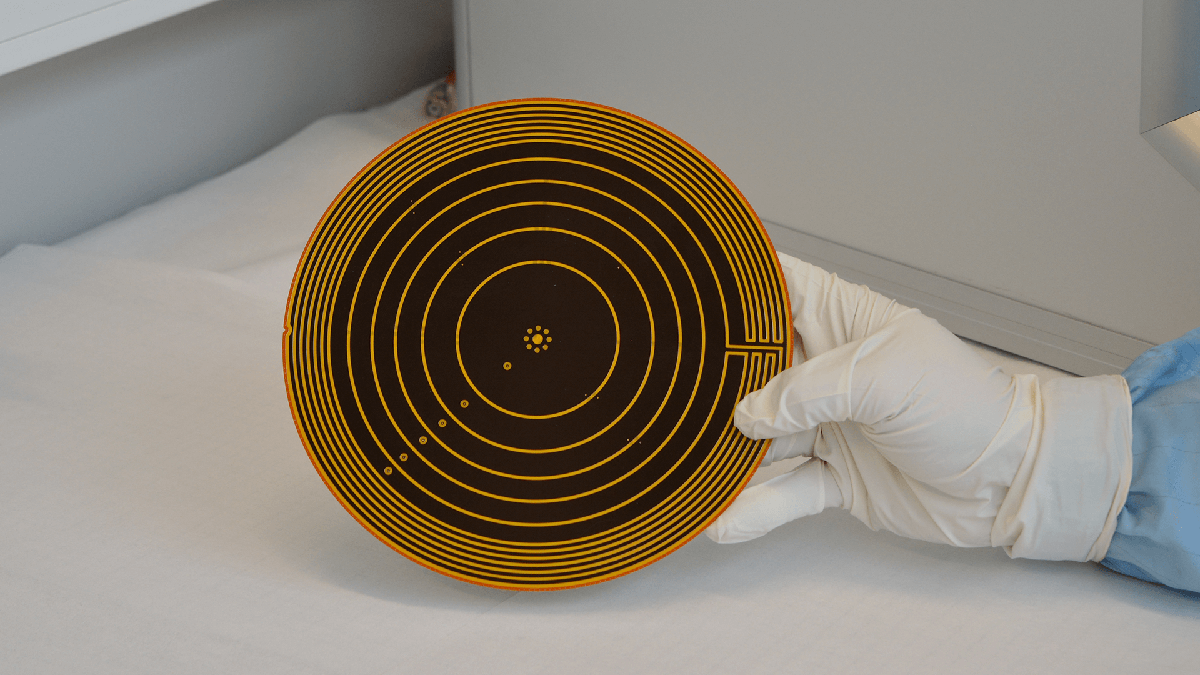

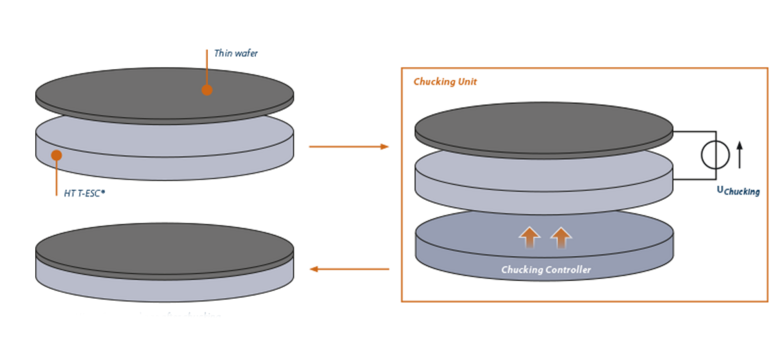

The Transferable Electrostatic Carrier (T-ESC®) is an adhesive-free temporary bonding method that enables the safe and reliable processing of fragile substrates and various materials such as ultra-thin substrates, GaAs, InP, LN, LT, thin silicon, thin MEMS wafers and many more. The basic concept behind this sustainable temporary bonding technology involves the use of electrostatic forces to chuck device wafers onto mobile rigid Carriers (T-ESC®).

These wafer-carrier packages can then be handled and securely processed like wafers of standard thickness through existing machines within the customer facility. Therefore, existing cassettes, handling tools and fabrication equipment can be used without modifications. Additionally, the warping and bowing of thin and ultra-thin substrates are eliminated. The Transferable Electrostatic Carriers are available in the standard sizes from 2" to 12" and in customized shapes adapted to the intended application.

The Adapter Carrier

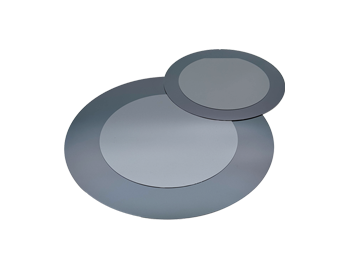

Each T-ESC® type is offered as an adapter version that allow machines to process device wafers of different diameters and forms. The smaller device wafer can be temporarily bonded to an Adapter Carrier and is held in position by electrostatic forces. For example, a 4”/8” Adapter T-ESC is suited to fixate a 4” wafer on an 8” Adapter T-ESC.

The package of a 4” wafer and an 8” Adapter Carrier can now be used in the intended equipment, e.g. an 8” Stepper. The Stepper tool recognizes a standard 8” substrate and can now process the smaller 4” wafer sizes.

Typical Applications

-

Thin wafer handling support during processes involving high temperature impact (up to 400 °C), vacuum-suited

-

Compatibility with existing handling systems (transport cassettes, vacuum, Bernoulli or mechanical end effectors, etc.)

-

Ultra low contamination

-

High flatness

-

Outgassing free

-

Reusable

-

Sizes from 2" to 12", customized shapes and features possible

SEMI conform package after chucking mounted wafer ready for application

-

Thickness of package ~750 μm

-

Package can be handled and processed by standard equipment

Recommended Processes

-

Electroplating

-

Annealing

-

DIE Handling

-

Handling

Handling

During the wafer processing the wafer needs to be transferred back and forth from the cassettes to the tools and also inside the tools from one station to the other. For fragile substrates this is already challenging, because they tend to break or get cracks, which can lead to future breakage. Also the bowing of thinned substrates brings a lot of trouble for all tooling because they are usually not designed for this very special operation. Temporary bonding with our T-ESC® is a great help here as the processing tools only see a standard wafer and trouble with handling. Therefore, the wafer breakage is eliminated.

Electro Plating

Electro Plating is a method for forming layers out of a liquid phase onto a substrate. The desired regions are masked and the substrate is dipped into the bath. Usually the backside is covered and by applying an electrical field between the substrate and the liquid a layer is formed on the uncovered surface of the substrate.

Annealing

The substrate is heated up to a specific temperature, e.g. after ion implantation to heal the damage from the process.

DIE Handling

Multiple substrate operations are often required when already diced DIEs need further processing in an economical way. Multiple of them can be temporarily bonded to our Mobile Electrostatic Carrier (T-ESC®) and processed as a standard wafer size. After that they can be transferred to the final substrate and bonded with releasing the T-ESC® afterwards.

Our Machines

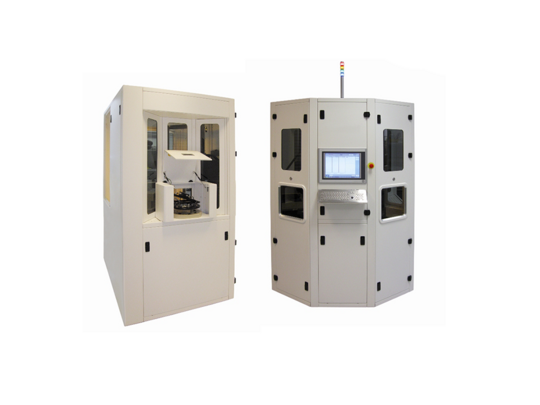

ACU 3000

A fully automated electrostatic chucking/ dechucking unit with up to 120 wafers and/or T-ESC® packages per hour, guaranteeing the highest yield during handling and many diagnostics features.

Learn More

MCU 3000

A manual chucking/ dechucking unit of thin and ultra-thin substrates on carriers (T-ESC®s) for flexible sizes from 4”/6” to 8”/12” with a high flexible mobile handling tool and diagnostics features.

Learn More